Screening Station KA 4018-3.5 – Composting Equipment

With a drum screen design, screening stations KA 4018 and KA 5020 are installed on concrete foundations to your desired height.

For the feed hopper, we offer two different options:

- As our basic solution, we offer a 3.5 m³ feed hopper attached directly to the station.

- Optionally, we can also provide standalone bunker units with capacities of up to 24 m³.

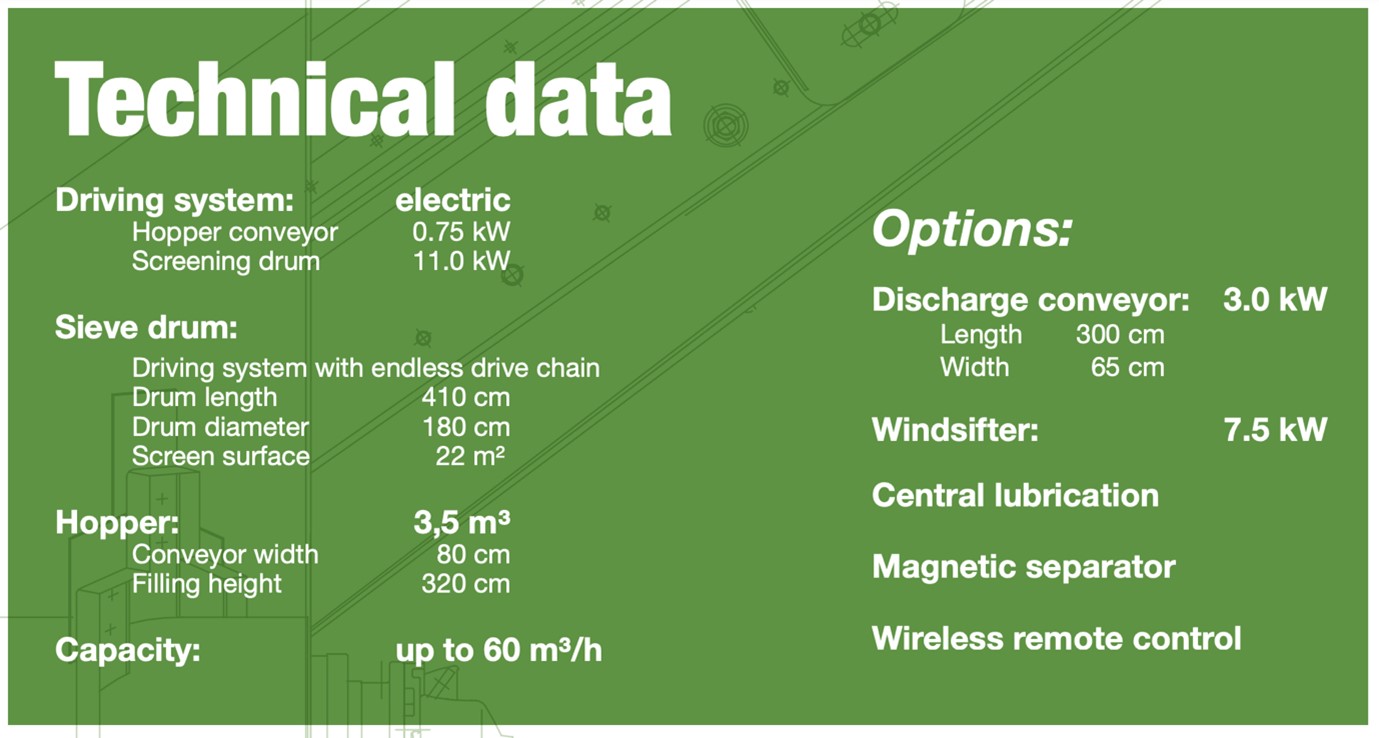

Screen overflow can be discharged via a conveyor belt, which can be equipped with an optional air separator to suck light plastic fractions out of the overflow, from where they can be blown into a separate container. Once free of impurities, the screen overflow can be re-fed into the composting process. The screening stations are electrically operated.

Powerful - Compact - Affordable

The KA 4018-3.5 is mounted on flexible system-foundation-blocks so that the customer can individually choose the height. The drum is driven by an electric motor-gear unit with step-less (FC) speed regulation. Feeding of the drum is either executed by a stationary bunker with a volume of 3,5 m³ and an FU-controlled conveyor belt. An optional air separator, mounted on the discharge conveyor of the screening station, separates the light fraction and directs it into a special container before the screen overflow is recirculated into the rotting process.